Basics of Fungicide Application in Oats

Ty Larson, Certified Crop Advisor

Agronomist, Albert Lea Seed

Farmers growing conventional oats can improve the yield, test weight, and quality of their oat crop with timely and appropriate use of fungicides. This article is intended as a basic guide to fungicide use in oats and should not replace consultation with your local professional agronomist. Always read and follow the label of all fungicides before beginning application.

Why Use Fungicides in Conventional Oat Production?

PREVENTION AND MINIMIZATION OF DISEASES

If unchecked, fungal diseases can cause widespread damage to oats. Fungicides help prevent the start and spread of diseases such as crown rust, powdery mildew, and leaf spot. By applying fungicides at critical growth stages, farmers can effectively reduce the risk of disease outbreaks and protect their oat crops throughout the growing season.

IMPACT ON QUALITY OF OATS

The quality of oats directly impacts their market value and suitability for potential customers. A fungal pathogen can not only reduce yield but can also compromise the test weight, nutritional value, and overall quality of the oats.

When a labeled fungicide is applied to an oat crop that is at risk of infection, the overall plant health is maintained or improved. A 2014-2016 study from North Dakota State University evaluated fungicides’ impact on the oat’s grain quality. In 2015-2016, a fungicide application improved the normalized difference vegetation index (NDVI) score of oats compared to ones that did not receive an application. This study supports the case that a fungicide application can help prevent foliar diseases and improve the crop’s plant health.

INFLUENCE ON OAT YIELD AND RELEVANCE OF ENVIRONMENTAL CONDITIONS

Yield is one of the most important things for an oat grower. A fungal pathogen can significantly hurt oat yields by stunting plant growth, reducing grain fill, and/or causing premature death of plant tissue. Fungicide applications play a significant role in protecting yield potential by suppressing disease development and keeping a crop healthy.

South Dakota State University routinely tests the impact fungicide application has on oat yields. During the 2020 growing season when conditions were fit for crown rust and other foliar diseases, the oats that received a fungicide application averaged 21 bu/acre and 3.2 lbs/bu better test weight than non-treated oats. However, when conditions do not favor the development of fungal diseases, the response to a fungicide application is negligible.

Understanding Fungicide Application

TIMING OF APPLICATION

Begin scouting at the 2-leaf stage and scout each field at least once a week.

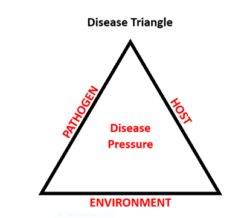

Increase scouting frequency when environmental conditions are favorable for disease development. Remember the disease triangle: all three factors must be present for a disease to occur.

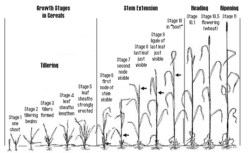

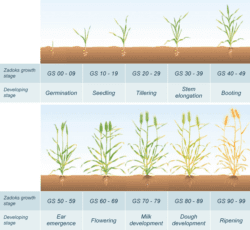

Generally, a suitable time to spray a fungicide is when the seed head is halfway out of the boot growth stage (Feekes 10.3 / Zadoks 55); potentially earlier depending on the fungicide used. Consult your local chemical representative for more information.

Feeks Growth Stages

Source: https://www.nue.okstate.edu/GSchart.htm

Zadoks Growth Stages

Determining appropriate rates

Follow the labeled rates and consult your local chemical representative if you have any questions.

Overview of active ingredients commonly used

The most common Modes of Action used are FRAC 3,7, & 11. Below are listed these Modes of Action and how they prevent fungal pathogens from infecting the plant, as defined by Rutgers University.

- FRAC Group 3-The DMI (DeMethylation Inhibitors) or Sterol Biosynthesis Inhibiting (SBI’s) fungicides belong to FRAC code 3 which include the triazoles and imidazoles. In any given field population, the sensitivity to the DMI fungicide by the fungus may range from extremely high (highly sensitive and will be controlled by fungicide) to moderate (partially sensitive to the fungicide) or low (mostly resistant to fungicide).

- FRAC Group 7-The SDHI (succinate dehydrogenase inhibitor) fungicides belong to FRAC group 7 which have been on the market since the late 1960s. Third generation SDHIs have been available since 2003 with the release of boscalid (penthiopyrad).

- FRAC Group 11- The strobilurin, or QoI fungicides (FRAC group 11) are extremely useful in controlling a broad spectrum of common pathogens. For example, FRAC group 11 active ingredients such as azoxystrobin are also now available in generics or in combination products.

More information on FRAC Groups 3 and 11 can be found here. More information about FRAC Group 7 can be found here.

Make sure you are rotating the Mode of Actions you use to prevent fungal pathogens from developing a resistance to a fungicide.

Where Should You Acquire Fungicides and Obtain Expert Advice on Rates?

Reliable sources for purchasing fungicides like a local co-op. They work hand in hand with chemical representatives and are up to date with current fungicide programs.

Guidance on determining suitable application rates

Follow the rates on the label. The label is the law. Agronomists are a great resource. They have the knowledge and expertise on how to prevent and/or identify fungal pathogens.

Neighbors and mentor farmers are a good starting point for recommendations. They can tell you what has worked for them and where you could purchase fungicides. As always, consult any of the above resources before you apply any fungicide to your crop.

Common Fungicide Programs in Oats

Examples of typical fungicide programs utilized in oat cultivation.

| Product | Active ingredient | FRAC Group | Timing | Rate in fl oz/A |

| Headline SC | Pyraclostrobin | 11 | Apply no later than the beginning of flowering (Feekes 10.5, Zadok’s 59) | 9 |

| Trivapro | Azoxystrobin + Benzovindiflupyr + Propiconazole | 11+7+3 | Apply prior to disease development for disease control and plant health benefits. Apply 9.4 fl oz/A after first tiller visible to 2-6 node stage (Feekes 2-7, Zadoks 21-36) for suppression of early season diseases; Apply no closer than 14 days apart.

For disease control on the flag leaf, apply from Feekes 8 (Zadoks 37) through Feekes 10 (Zadoks 45). Protecting the flag leaf is important for maximizing the potential yield and plant health benefits. Highest yields are normally obtained if Trivapro Fungicide is applied when the flag leaf is 50% to fully emerged. Applications may be made no closer than a 14-day interval. Trivapro Fungicide can be applied through full head emergence (Feekes growth stage 10.5.4). Do not apply after this stage to avoid possible illegal residues. |

9.4-13.7 |

| Stratego | Propiconazole + Trifloxystrobin | 3+11 | Feekes 8.0 (flag leaf emerged) | 7 |

| Tilt | Propiconazole | 3 | Apply Tilt in the spring. Follow up with a second application up to Feekes growth stage 10.5.4 for season long control.

Applications may be made no closer than a 14-day interval. Protecting the flag leaf is important for maximizing the potential yield. Highest yields are normally obtained when Tilt is applied when the flag leaf is 50% to fully emerged. |

2-4 |

| Approach | Picoxystrobin | 11 | Make a single application between tillering through jointing for early season disease control/suppression. No sooner than 7 days later, additional 6 fl oz to 12 fl oz treatments can be made depending on disease pressure and environmental conditions.

Begin applications prior to disease development and make a second application on a 7- to 14-day interval, depending on the targeted disease. Use the higher specified rate and shorter intervals when disease pressure is high. To optimize yields in cereals, it is important to protect the flag leaf from foliar diseases. For optimizing yield and flag leaf disease control, apply Aproach at Feekes 9, ‘flag leaf out’. Apply no later than the beginning of flowering (Feekes 10.5). |

2-4, 6-12 |

| Quilt Xcel | Propiconazole + Azoxystrobin | 11+3 | Make a single application between tillering through jointing for early season disease control/suppression. No sooner than 7 days later, additional 6 fl oz to 12 fl oz treatments can be made depending on disease pressure and environmental conditions.

Protecting the flag leaf is important for maximizing the potential yield. Highest yields are normally obtained when quilt xcel fungicide is applied when the flag leaf is 50% to fully emerged. |

7-14, 10.5-14 |

| Aframe Plus | Propiconazole + Azoxystrobin | 3+11 | Apply Aframe Plus in the spring for suppression of early season diseases. Follow up with a second application (see below) for full season control.

Protecting the flag leaf is important for maximizing the potential yield. Highest yields are normally obtained when Aframe Plus is applied when the flag leaf is 50% to fully emerged. Applications may be made no closer together than a 14-day interval. |

7-14 |

| Priaxor Xemium | Fluxapyroxad + Pyraclostrobin | 7+11 | Apply no later than 50% head emergence (Feekes 10.3, Zadok’s 55) but no less than 21 days before harvest | 4-8 |

Fungicide Programs from Oat Experts:

FROM A THIRD-GENERATION SEED OAT GROWER IN SOUTHERN MINNESOTA:

“I start scouting my fields before the third leaf appears, aiming to do my first fungicide pass between the 3-4 leaf stage with 7 fl oz/A of Aframe, 16 fl oz/A of a broadleaf herbicide, and 6.4 fl oz/A of a micronutrient. Next, I’ll follow up with another pass of Aframe (if needed) and 12.5 fl oz/A of Palisade (plant growth regulator) if the oat variety is a full-season one. I aim to complete this second application before the flag leaf stage. I’ve had good success with this program and routinely average yields of over 100 bushels an acre.”

FROM A SEED COMPANY OWNER AND SUCCESSFUL OAT GROWER IN SOUTHERN MINNESOTA:

“I begin checking my fields before the boot stage and like to spray my oats with Trivapro 9.4-11 fl oz /A at the heading stage. I apply fungicide on the lower end of the recommended rates, because I’ve had problems with some of my oats still being green at harvest. I mix it with broadleaf herbicide, if warranted, and/or seed with a legume. I’ve found that a one-pass system with Trivapro (a fungicide with a wider application window and a long residual) has given me the best return on investment.”

FROM A COOPERATIVE IN SOUTHERN MINNESOTA THAT WORKS WITH NUMEROUS OAT GROWERS:

“We begin scouting fields when oats are 4-8 inches tall. Currently, we’re using a one-pass system with either Priaxor Xemium at 8 fl oz/A or Quilt Xcel at 14 fl oz/A, with Quilt Xcel being the standard fungicide we prescribe. We will apply one of these fungicides at no later than 50% head emergence. A broadleaf herbicide is added if necessary. We’ve found that as a grass crop, oats respond very well to fungicide and encourage such applications as a worthwhile investment.”

Considerations for selecting a fungicide program tailored to specific needs.

- Determine what pathogen is most likely to occur or is present. Different fungal pathogens require different modes of action.

- Determine the severity or pressure of the disease. Accessing the disease pressure will tell you if you need to apply a fungicide or not.

- Determine which Mode of Action to use. Select a mode of action to control pathogens that have been identified or could be an issue.

- Residual activity. Some fungicides offer long-lasting protection, while others must be applied more frequently.

- Cost. Evaluate the cost-effectiveness of different fungicide options, making sure that the fungicide has a positive return on investment.

Conclusion

Overall, a fungicide application will help with disease prevention, preserve quality, and influence yield. Both timing and rate of an application is just as important as the mode of action used; without proper timing and the right rate, your fungicide will not give you the results you desire. It is crucial to rotate modes of actions to prevent the development of fungicide-resistant pathogens. Before applying any fungicide, it is important to consult your local agronomist and chemical dealers for guidance and help tailoring a fungicide program to your specific needs. Additionally, consulting your local extension office can provide valuable insights and further guidance.

I encourage you to take this information provided and use it to develop a personal fungicide program.

___

Additional Resources:

- University of Minnesota Extension website: https://extension.umn.edu/crop-production

- North Dakota State University Extension Website: https://www.ndsu.edu/agriculture/extension

- Penn State University Extension website: https://extension.psu.edu/forage-and-food-crops/agronomic-crops

- Rutgers University Extension Website: https://njaes.rutgers.edu/county

- South Dakota State University Extension website: https://extension.sdstate.edu/agriculture

- University of Wisconsin Extension website: https://extension.wisc.edu/agriculture

- Practical Farmers of Iowa: https://practicalfarmers.org